New and available worldwide: Bio-based TPE

TPEs from renewable raw material sources with a lower product carbon footprint.

KRAIBURG TPE responds to the issue of bio-based materials by supplying bio-based TPEs with a variable proportion of sustainable raw materials.

KRAIBURG TPE is presenting thermoplastic elastomers (TPEs) that have a variable proportion of renewable raw materials. By introducing these new compounds, the global TPE manufacturer is expanding its THERMOLAST®R range of more sustainable solutions by adding a line of products from renewable raw material sources. Bio-based TPEs also have a lower product carbon footprint than established alternatives that are not based on renewable raw materials.

With bio-based TPEs, we are filling a gap in our portfolio and taking another step toward more sustainable TPEs. Our bio-based TPEs provide more sustainable solutions, while maintaining the usual performance and reducing the product carbon footprint.

Dr. Tobias Brückner | Project Manager Advance Development at KRAIBURG TPE

Waldkraiburg, 17 October 2023 – Sustainability is a key aspect of the design phase. It is only when the idea of sustainability plays a major role from the very start of a project that it can contribute to the project’s success in the longer term. KRAIBURG TPE’s customers already have access to more sustainable compounds that contain proportions of post-industrial or post-consumer recycled materials, particularly in the consumer and automotive sectors. KRAIBURG TPE is now complementing its range of more sustainable solutions by adding bio-based TPEs made of raw materials that support the transition from compounds based on fossil resources to alternative products based on renewable materials and make this transition attractive.

When evaluating new raw materials for bio-based TPEs, KRAIBURG TPE is focusing on materials that are not used for food production. These are raw materials such as agricultural by-products or waste materials from food production that cannot be used as food even if they are further processed. KRAIBURG TPE critically evaluates the origin of raw materials in order to meet the company’s high self-imposed requirements. By working closely with suppliers, KRAIBURG TPE ensures a delivery capability for bio-based and recycled raw materials comparable to that for conventional base polymers.

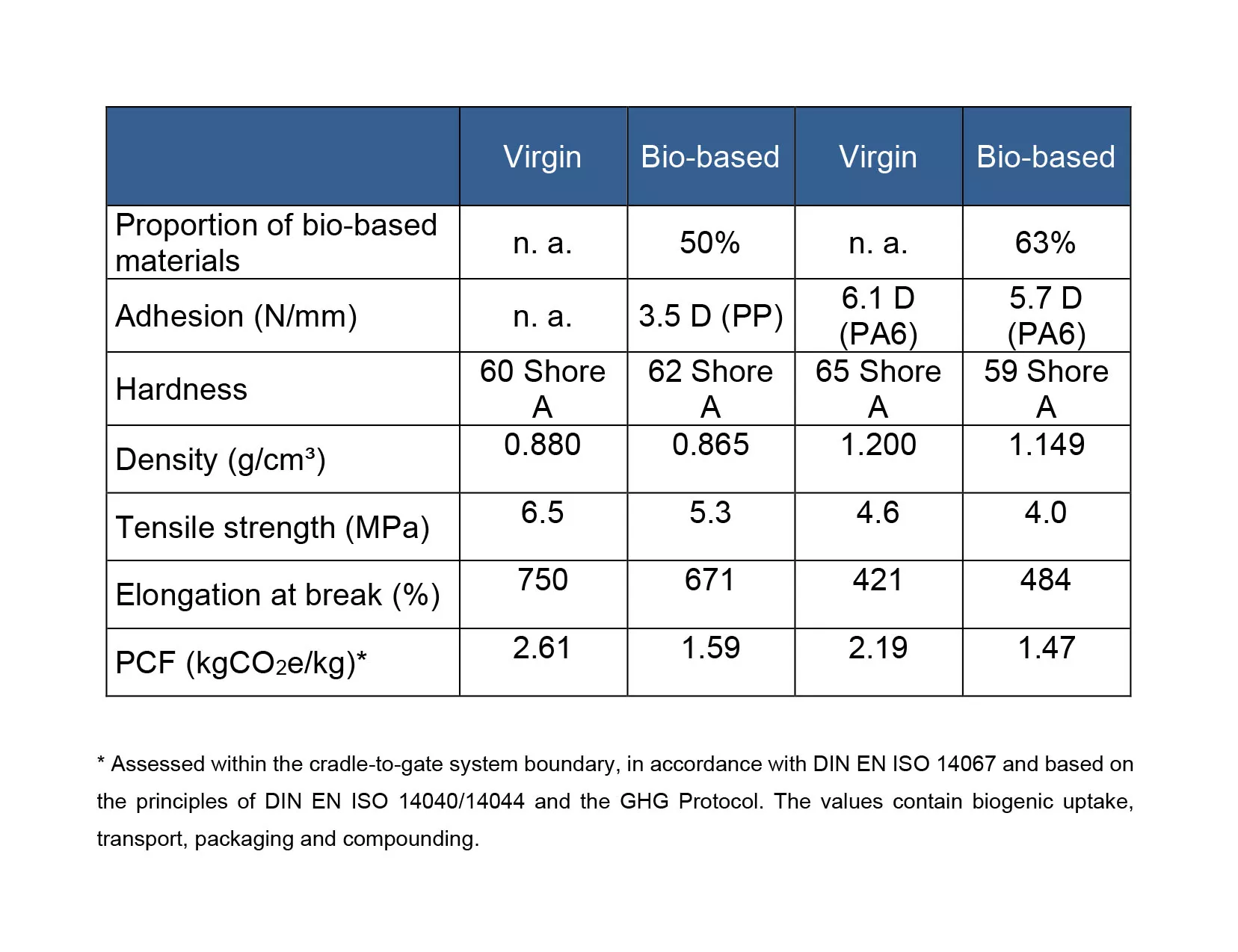

Using bio-based TPEs can reduce a product’s carbon footprint (PCF) by up to 50 percent as compared to TPEs made of fossil-based materials. PCF refers to the total amount of greenhouse gas emissions, particularly carbon dioxide (CO2), associated with the production, usage and disposal of a particular product or service. Transparency and understanding the PCF can enable end customers and processing companies to make informed decisions when selecting materials in order to produce and market more sustainable products. This aspect is currently of interest in all markets where there’s a demand for materials with reduced carbon footprints. By using renewable raw materials in the production of bio-based TPEs, KRAIBURG TPE is actively helping customers to achieve their sustainability targets.

Bio-based TPEs provide neutral odor, touch, grip and adhesion properties that are highly comparable to those of fossil-based TPEs. The new products include solutions such as compounds with adhesion to PP, ABS/PC and PA within a hardness range between 30 and 85 Shore A. Individual compounds have a bio-content of more than 60%. Both compounds with adhesion to PP and to polar materials can be colored. The materials have been thoroughly tested in injection molding and extrusion and have processing properties comparable to those of fossil-based TPEs.

“With bio-based TPEs, we are filling a gap in our portfolio and taking another step toward more sustainable TPEs. Our bio-based TPEs provide more sustainable solutions, while maintaining the usual performance and reducing the product carbon footprint. We are looking forward to projects that enable us to make the transition from fossil-based to more sustainable raw materials,” sums up Dr. Tobias Brückner, Project Manager Advance Development at KRAIBURG TPE.

Bio-based TPEs are currently produced in Germany and are available worldwide immediately.

- Traceable bio-based/biogenic carbon content according to ASTM D 6866

- Adhesion to Polyolefins, PC, ABS, PC/ABS or PA

Christina Havlicek

Market Manager Consumer at KRAIBURG TPE

Phone: +49 8638 9810-293

Mobile: +49 162 7651755

E-Mail: christina.havlicek@kraiburg-tpe.com

New and available worldwide: Bio-based TPE

TPEs from renewable raw material sources with a lower product carbon footprint.

KRAIBURG TPE responds to the issue of bio-based materials by supplying bio-based TPEs with a variable proportion of sustainable raw materials.

KRAIBURG TPE is presenting thermoplastic elastomers (TPEs) that have a variable proportion of renewable raw materials. By introducing these new compounds, the global TPE manufacturer is expanding its THERMOLAST®R range of more sustainable solutions by adding a line of products from renewable raw material sources. Bio-based TPEs also have a lower product carbon footprint than established alternatives that are not based on renewable raw materials.

Waldkraiburg, 17 October 2023 – Sustainability is a key aspect of the design phase. It is only when the idea of sustainability plays a major role from the very start of a project that it can contribute to the project’s success in the longer term. KRAIBURG TPE’s customers already have access to more sustainable compounds that contain proportions of post-industrial or post-consumer recycled materials, particularly in the consumer and automotive sectors. KRAIBURG TPE is now complementing its range of more sustainable solutions by adding bio-based TPEs made of raw materials that support the transition from compounds based on fossil resources to alternative products based on renewable materials and make this transition attractive.

When evaluating new raw materials for bio-based TPEs, KRAIBURG TPE is focusing on materials that are not used for food production. These are raw materials such as agricultural by-products or waste materials from food production that cannot be used as food even if they are further processed. KRAIBURG TPE critically evaluates the origin of raw materials in order to meet the company’s high self-imposed requirements. By working closely with suppliers, KRAIBURG TPE ensures a delivery capability for bio-based and recycled raw materials comparable to that for conventional base polymers.

Using bio-based TPEs can reduce a product’s carbon footprint (PCF) by up to 50 percent as compared to TPEs made of fossil-based materials. PCF refers to the total amount of greenhouse gas emissions, particularly carbon dioxide (CO2), associated with the production, usage and disposal of a particular product or service. Transparency and understanding the PCF can enable end customers and processing companies to make informed decisions when selecting materials in order to produce and market more sustainable products. This aspect is currently of interest in all markets where there’s a demand for materials with reduced carbon footprints. By using renewable raw materials in the production of bio-based TPEs, KRAIBURG TPE is actively helping customers to achieve their sustainability targets.

Bio-based TPEs provide neutral odor, touch, grip and adhesion properties that are highly comparable to those of fossil-based TPEs. The new products include solutions such as compounds with adhesion to PP, ABS/PC and PA within a hardness range between 30 and 85 Shore A. Individual compounds have a bio-content of more than 60%. Both compounds with adhesion to PP and to polar materials can be colored. The materials have been thoroughly tested in injection molding and extrusion and have processing properties comparable to those of fossil-based TPEs.

“With bio-based TPEs, we are filling a gap in our portfolio and taking another step toward more sustainable TPEs. Our bio-based TPEs provide more sustainable solutions, while maintaining the usual performance and reducing the product carbon footprint. We are looking forward to projects that enable us to make the transition from fossil-based to more sustainable raw materials,” sums up Dr. Tobias Brückner, Project Manager Advance Development at KRAIBURG TPE.

Bio-based TPEs are currently produced in Germany and are available worldwide immediately.

KRAIBURG TPE Quick Facts

- Founded in 2001 as an independent business unit of the KRAIBURG Group

- HQ & Production Site: Waldkraiburg / Germany

- Regional HQ & Production site: Kuala Lumpur / Malaysia, Atlanta / USA

- Products: Thermoplastic Elastomer Compounds

- Brands: THERMOLAST®, COPEC®, HIPEX®, and For Tec E®

- Markets: EMEA, APAC, Americas

- Employees: 660